Fiberglass fertilizer tanks are the answer to the familiar problem caused when mild steel tanks get eaten away. Highly corrosive liquids seem to have an appetite for mild steel. True, stainless never rusts… but the cost is high for most installations.

Fiberglass makes better liquid fertilizer storage tanks than mild steel (or stainless) for 3 good reasons!

Fiberglass makes better liquid fertilizer storage tanks than mild steel (or stainless) for 3 good reasons!

- FIBERGLASS NEVER RUSTS – Fiberglass is the NEVER RUST answer to the familiar problem caused when mild steel tanks get eaten away. Highly corrosive liquids seem to have an appetite for mild steel. True, stainless never rusts… but the cost is high for most installations.

- FIBERGLASS IS MAINTENANCE FREE – Forget the yearly drudgery and expense of tank maintenance. When you consider the high cost to maintain a mild steel tank farm (over a period of years) you’re ready for maintenance-free fiberglass.

- FIBERGLASS COSTS LESS – Large capacity fiberglass ag tanks always cost less than stainless fertilizer tanks of the same height and diameter. In the long run, mild steel tanks cost more than fiberglass, when you consider the high cost to maintain mild steel fertilizer tanks (over a period of years).

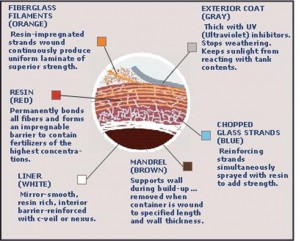

Wall Construction

Each area of the cross section of the wall structure, provides an important part of the total design. Properly designed and constructed, fiberglass provides years of dependable service.

Proper choice of the resin type, corrosion resistant liner and wall structure thickness for the intended purpose are all important factors . . . areas where Enviropac can assist in the right choices for your requirements.

Filament Wound Tank in Fabrication

Fabricating operations take place on a cylindrical mandrel of the diameter and length equal to the size of the tank. A precisely controlled wall thickness is achieved by filament winding in combination with sprayed resins and chopped-glass stands.

When you plan to add or replace your mild steel tanks, ask for assistance from people who understand the business . . . someone who speaks you language.

- Mandrel supports tank during build-up

- Mylar on Mandrel provides smooth interior surface

- Filament winding & chopped strands add to structural strength

- Gel-Coat or Pigmentation on exterior stops weathering

CUSTOM FITTING & ACCESSORIES OF CHOICE

Custom design the tank for your operation. Need additional inlets/outlets, sparging, re-circulation . . . standard and custom fittings are available.

Manways provide easy access to the interior of the tank and are positioned on the tank wall or roof.

Sight gauges (right), float gauges or ultrasonic gauging systems are available to correctly monitor inventory of product.

Heavy-duty base anchors and side anchor loops are available. Tank diameter, overall height, wind load and seismeic considerations are all variables that determine the type and number of anchor lugs needed.

Lift lugs (not shown) are provided to properly handle tanks in the loading/unloading process and to position the tank in the containment structure.

- Items shown above are typical

- Fittings installed may vary in appearance.

PRODUCTS STORED IN FIBERGLASS TANKS

Following is a partial list of products that can be stored in Fiberglass Tanks

28% or 32% UAN

Ammonium Sulfate

Ammonium Nitrate

Potassium Carbonate

Fertilizer Solutions

Ammonium Thiosulfate

Ammonium Bisulfite

Potassium Hydroxide

Phosphoric Acid (10-34-0, 3-10-30, 7-21-7, etc.)

Aqua Ammonia

N-pHURIC 15/49

Potassium Phosphate

NOTE: Resin, corrosion barrier & wall structure may vary depending on product stored

SHIPPING METHODS

Proper shipping methods for oversize tanks are important to consider.

To assure all tanks arrive at your job site in a safe and timely manner, Enviropac will arrange for special custom designed truck/trailer delivery throughout the contiguous USA.

WARRANTY INFORMATION

Storage tanks supplied by Enviropac, Inc. carry the manufacturers’ warranty and these are the only warranties which apply to the storage structure.

Enviropac, Inc. is not the manufacturer of the storage structure. The warranties of the manufacturer are the only warranties which apply to the storage structure. Enviropac, Inc. makes no warranties regarding the storage structure, either express or implied (including but not limited to implied warranty of merchantability and implied warranty of fitness for a particular purpose).